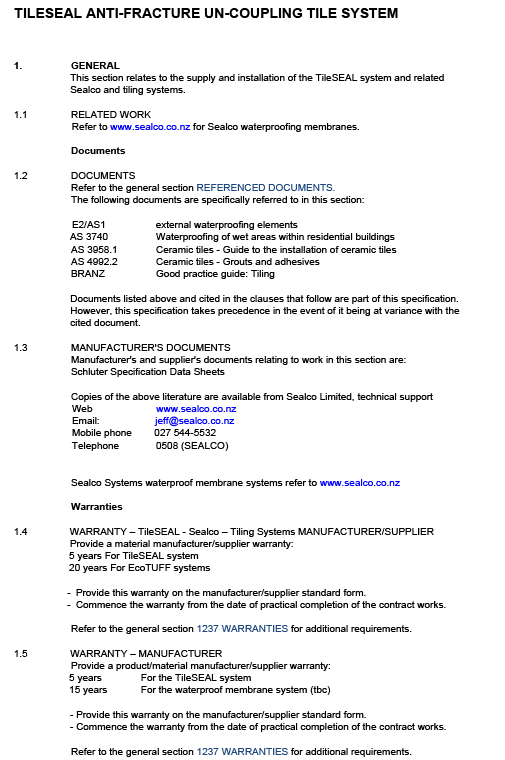

Commercial

In the construction of new public and private buildings,technological developments and a heightened attention to aesthetics have led to increased compliance with a series of rules and requirements, such as energy self-sufficiency, home automation and optimal user welfare. Sealco Interior Solutions has developed a series of systems - in particular for bathrooms - that allow the designer to design spaces that were previously unthinkable with the use of traditional materials, and allow the end customer to customise the bathroom in line with their own tastes and requirements.

Residential

When the bathroom renovators move in...any home owner would probably rather move to another planet than face the endless days of work, noise, dust, cement, etc. etc. With the Sealco Interior Solutions system and materials, bathroom renovations are quick and flexible: an important aspect, whether you are renovating the entire room (relaying the screed, moving the fixtures and lights, or even building a second bathroom) or just some of its elements (minor changes or additions, such as replacing a bathtub with a shower box). And all this with the further advantage of having minimum wall loads in the event of renovating attics.

Features and advantages

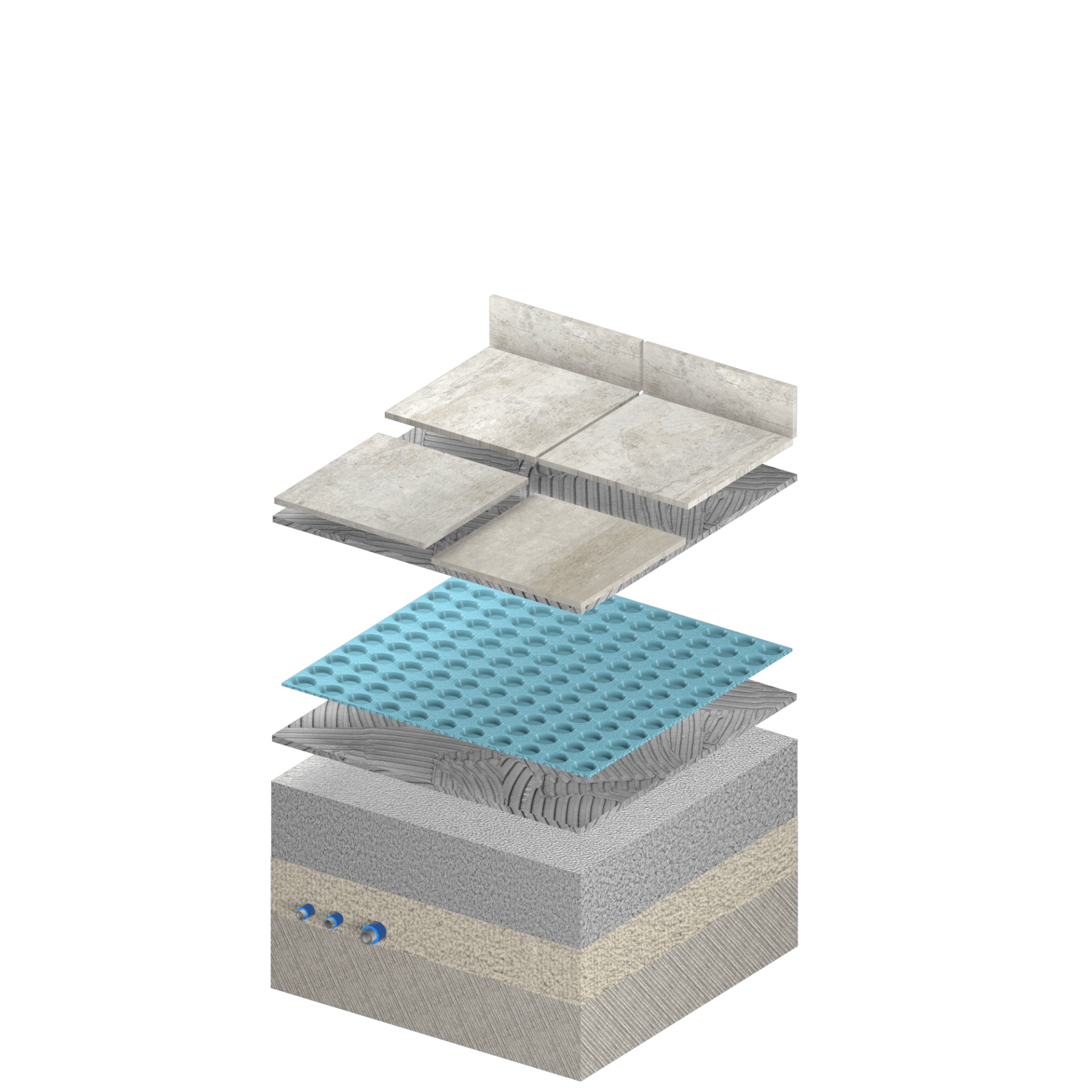

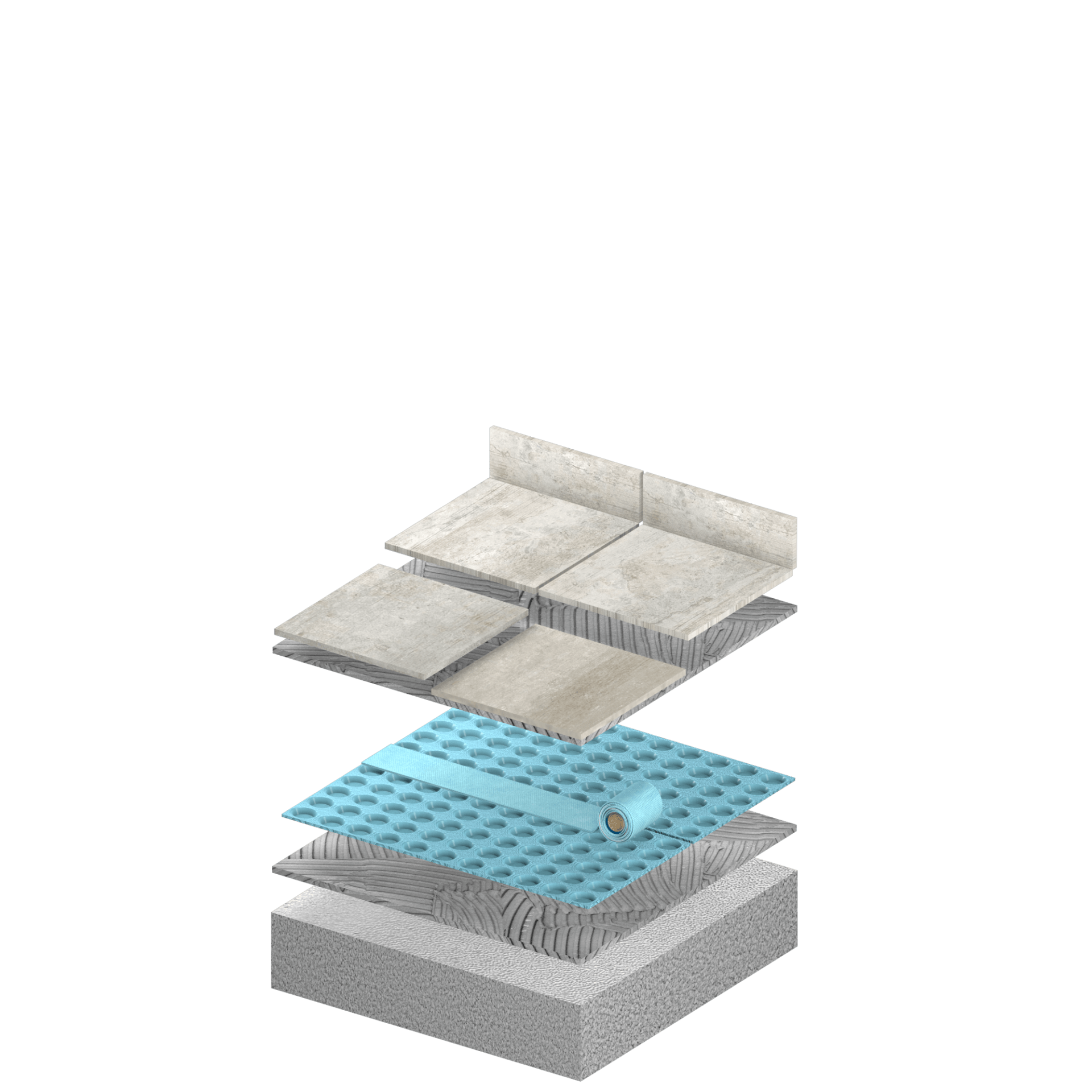

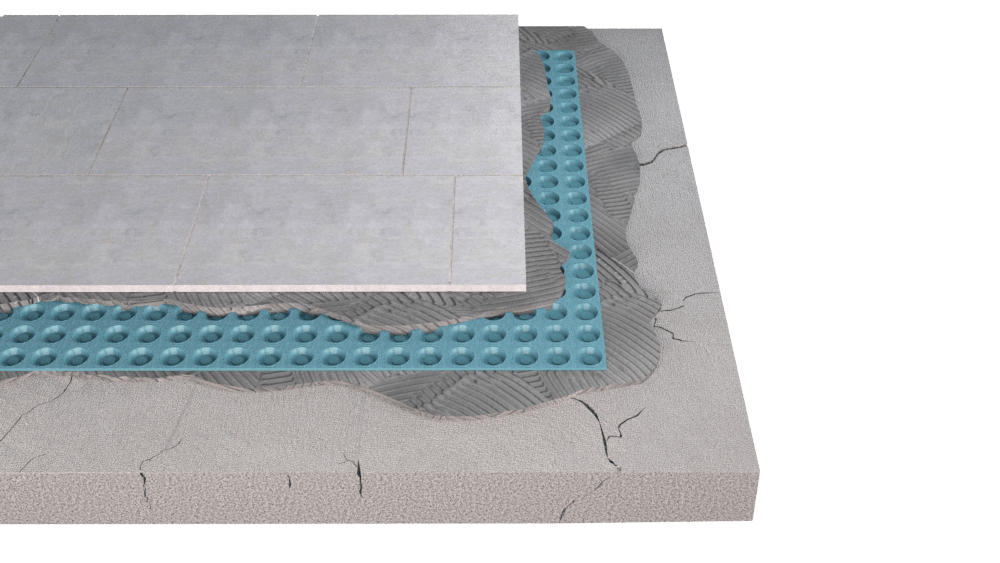

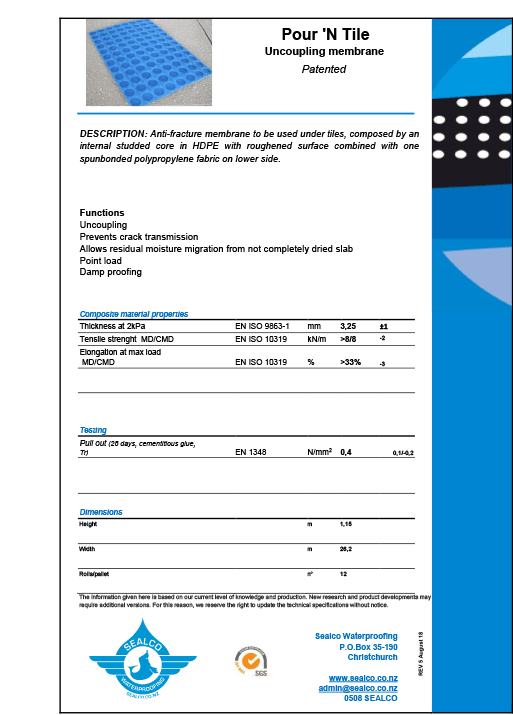

By using crack isolation systems, such as anti-fracture membranes, it is possible to minimise the transmission of stress and movement to the finished flooring material. This helps to protect the integrity and appearance of the flooring, reducing the likelihood of cracks or fractures and prolonging its lifespan.

Stresses in the subfloor - concrete floors will continue to shrink and expand for long periods after installation. Wooden substrates can be affected by moisture in the air. Over recent years the growth in heated flooring has dramatically increased the degree of movement within such floors. This “hot and cold” cycle places great stress on the tiled covering.

TileSEAL Antifracture is ideal for your tiling over membrane systems because:

- Ideal and approved for use over EcoTUFF TPO, EpiSPAN EPDM & other Sealco membranes

- Approved for use with a wide range of tiles

- Quick to install

- Simple to use

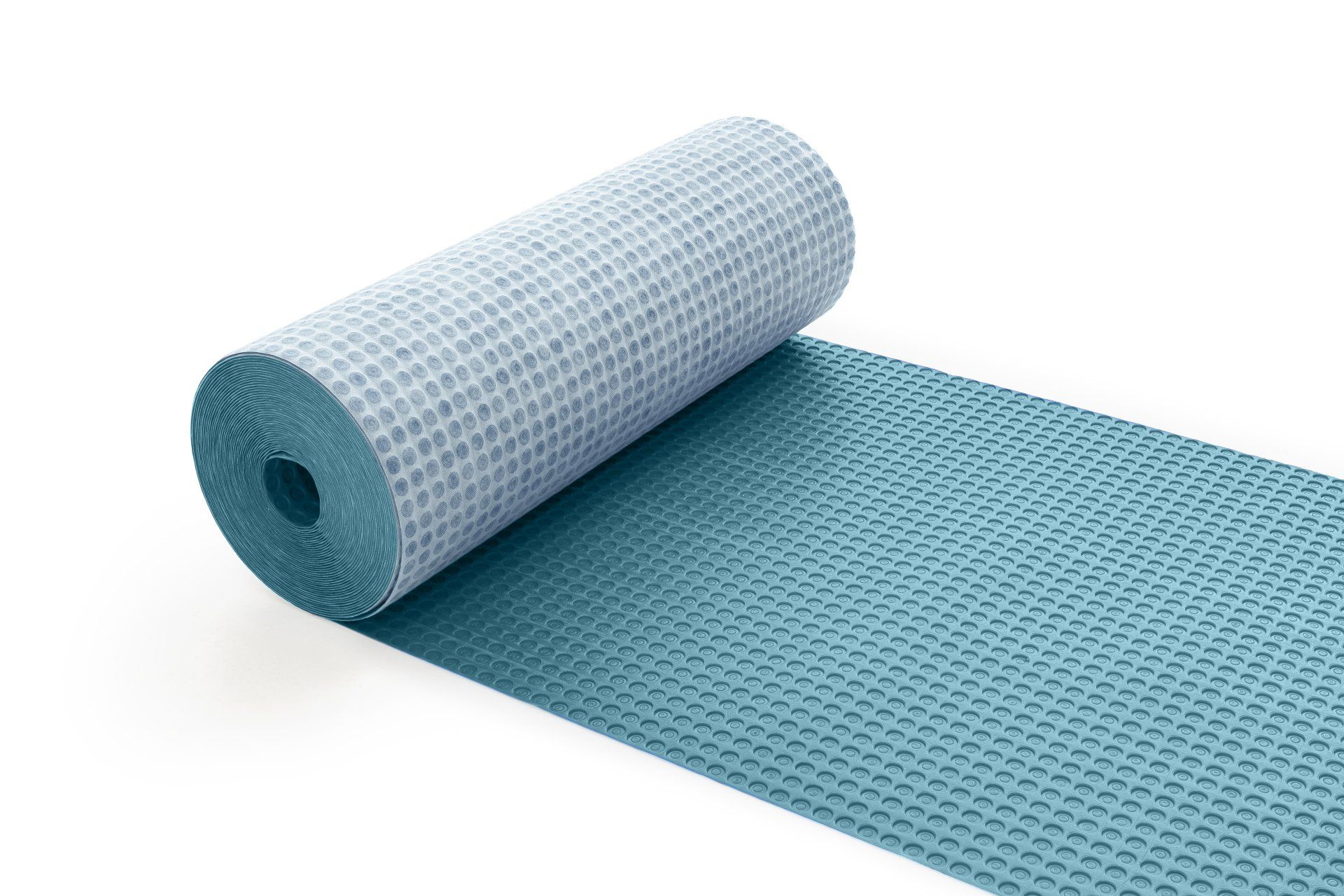

- Slim and lightweight

- Cost effective

- Versatile for many substrates

Cracks in both new and existing subfloor - these can be transmitted through into the tiles leaving your newly laid stone cracked.

Damp from the subfloor - The air channels within the design of anti- crack matting membrane allow moisture that would be otherwise trapped escape. This controlled “release” prevents problems within moisture sensitive substrates. This is particularly important when laying onto anhydrite subfloors, residual moisture from the screed itself can collect under the tiles and cause damage to the adhesive layer. Particular attention should be made to the residual moisture in such projects before work commences.